Your Address : Globalchemmade--Krofta Engineering Limited

Name:Krofta Engineering Limited

Type:Others

Tel:+(91)-(11)-47242500

Fax:

Address:China(Mainland)

Equipents offer detail

| Equipment: | Sequencing Batch Reactor |  |

| Equipment Type: | Reaction Equipment -> Reactor | |

| Unit Type: | ||

| Place Of Origin: | ||

| Price: | Inquire | |

| Valid Period: | ||

| Technical Parameters: | ||

| Usage: | ||

| Main Features: | ||

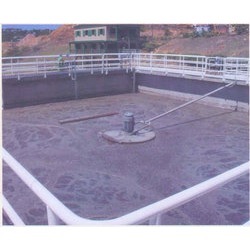

| Description: | Sequencing Batch Reactor Krofta SBR is an aerobic biological system that has been successfully used to treat both municipal sewage and industrial wastewater. The SBR process has been extensively used worldwide over the past decades, by collecting the raw wastewater in a batch reactor and decanting the treated wastewater after eliminating pollutants i.e. BOD, COD, TSS, nitrogen and phosphorous. The process is conducted in an alternating aerobic / anoxic / aerobic conditions by a batch process of filling (introduction of raw wastewater), aeration (for bacteria respiration), settling (solid separation) and decanting (final effluent evacuation and removal). Advantages: Tolerates Variable Hydraulic Loads Tolerates Variable Organic Loads Controls Filamentous Growth Provides Ideal Quiescent Settling BASIC PROCESS DESCRIPTION: FILLING: Tank is filled with the incoming waste-water. To enable maintaining of most optimized F/M ratios, waste water is taken into the tank by way of a quick yet controlled method. Helps as an enhancer for bacterial growth for better settling. REACTION: During this period aeration continues until complete biodegradation of BOD and nitrogen is achieved. After the substrate is consumed famine stage starts. During this stage some microorganisms will die because of the lack of food and will help reduce the volume of the settling sludge. The length of the aeration period determines the degree of BOD consumption. SETTLE: Aeration is discontinued at this stage and solids separation takes place leaving clear, treated effluent above the sludge blanket. During this clarifying period no liquids should enter or leave the tank to avoid turbulence in the supernatant. DRAW: This period is characterized by the withdrawal of treated effluent from approximately two feet below the surface of the mixed liquor by the floating solids excluding decanter. This removal must be done without disturbing the settled sludge. IDLE: The time in this stage can be used to waste sludge or perform backwashing of the jet aerator. The wasted sludge is pumped to an anaerobic digester to reduce the volume of the sludge to be discarded. The frequency of sludge wasting ranges between once each cycle to once every two to three months. Model KSBR-10 Max. Flow (KLD) 10.0 MOC of Reactor RCC / MS / FRP RCC / MS / FRP KSBR-25 25.0 KSBR-50 50.0 RCC / MS / FRP KSBR-100 100.0 RCC / MS / FRP KSBR-200 250.0 RCC / MS KSBR-300 KSBR-500 300.0 500.0 RCC / MS RCC / MS | |