Your Address : Globalchemmade--Krofta Engineering Limited

Name:Krofta Engineering Limited

Type:Others

Tel:+(91)-(11)-47242500

Fax:

Address:China(Mainland)

Equipments detail

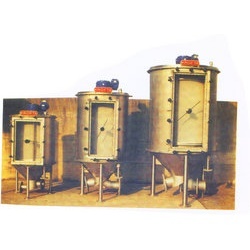

| Equipment: | Spray Filter |  |

| Equipment Type: | Auxiliary Equipment -> Filter Gauze & Filter Screen | |

| Unit Type: | ||

| Technical Parameters: | ||

| Post Time: | 2010-09-28 | |

| Main Features: | ||

| Usage: | ||

| Description: | Performance: The degree of fractionation and/ or microstraining depends on many factors; inlet consistency, spray pressure, inlet filler content, micron opening size, and particularly fines content of the fiber fraction. The following results can be expected: Coarse impurities are separated out. All the water ismicrostrained. The fiber fraction is retained by the cloth and can be recovered. Changes in fiber content by the KROFTA Spray Filter are minimized so that subsequent clarifiers operate under a uniform load. The KROFTA Spray Filter improves the operation of clarifiers especially floatation ones, as it aerates the effluent making it more adaptable to floatation. Measurements / Capacities Type Flow Flow Outside overall GPM LPM Dimension Height 500 132 500 3'''' 0" 6'''' 0" 1000 264 1000 3'''' 0" 6'''' 0" 2000 528 2000 3'''' 5" T 9" 3000 790 3000 3'''' 5" 8'''' 2" 4500 1185 4500 6'''' 8" 8'''' 2" 6000 1580 6000 6'''' 8" g, 2„ 7200 2000 7570 6'''' 8" 11'''' 9" Application : DE-INKING PLANTS : Separation of good fibers from fines and ink for a higher yield, less clay content in the stock and reduced disposal requirements. BOARD MILLS : Fractionation of the longer fibers from the effluent for use in the liner stock, while the fine fraction is used in the filler stock. Fine Paper And Tissue Mills: Recovery of fiber through the fractionation of the effluent thus reducing total sludge volume. Microstraining of the effluent for showers : Used to prevent the plugging of shower nozzles when either clarified or unclarified water is used. | |